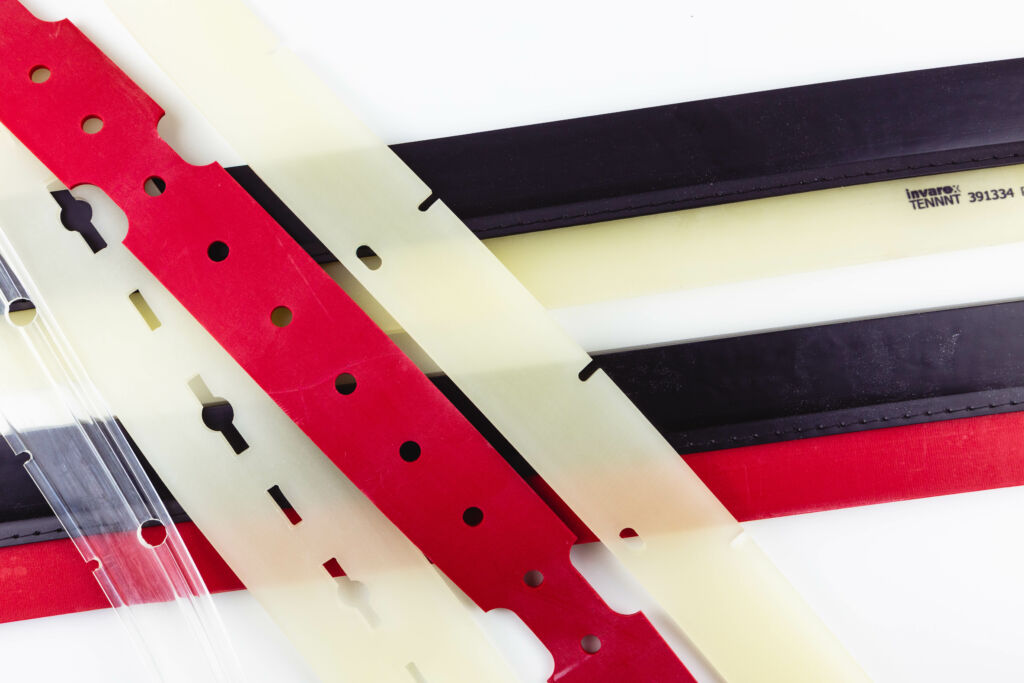

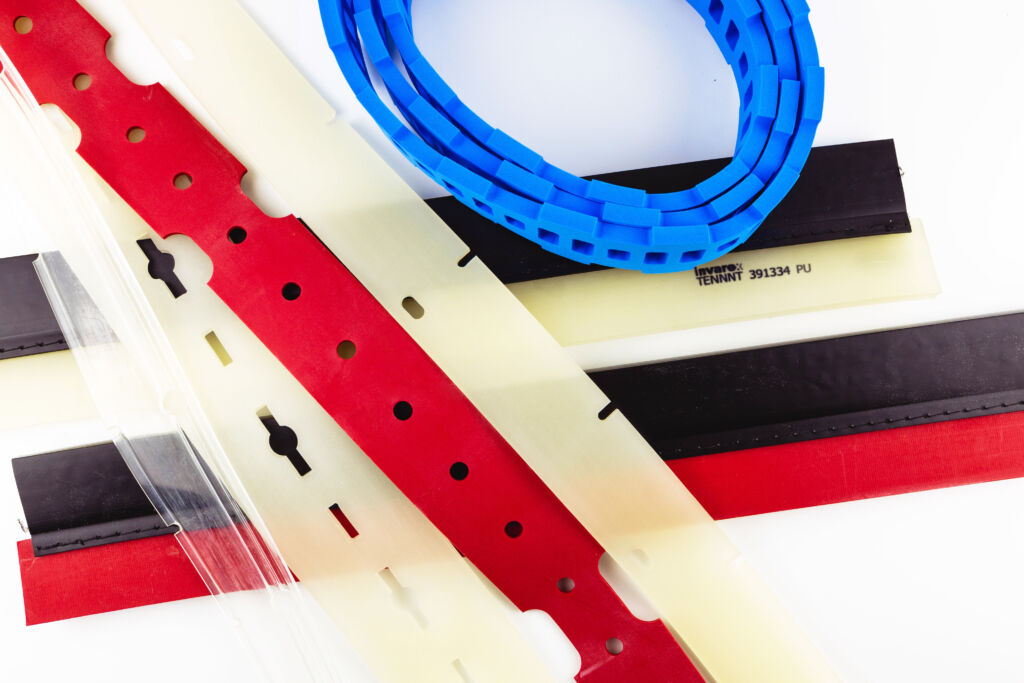

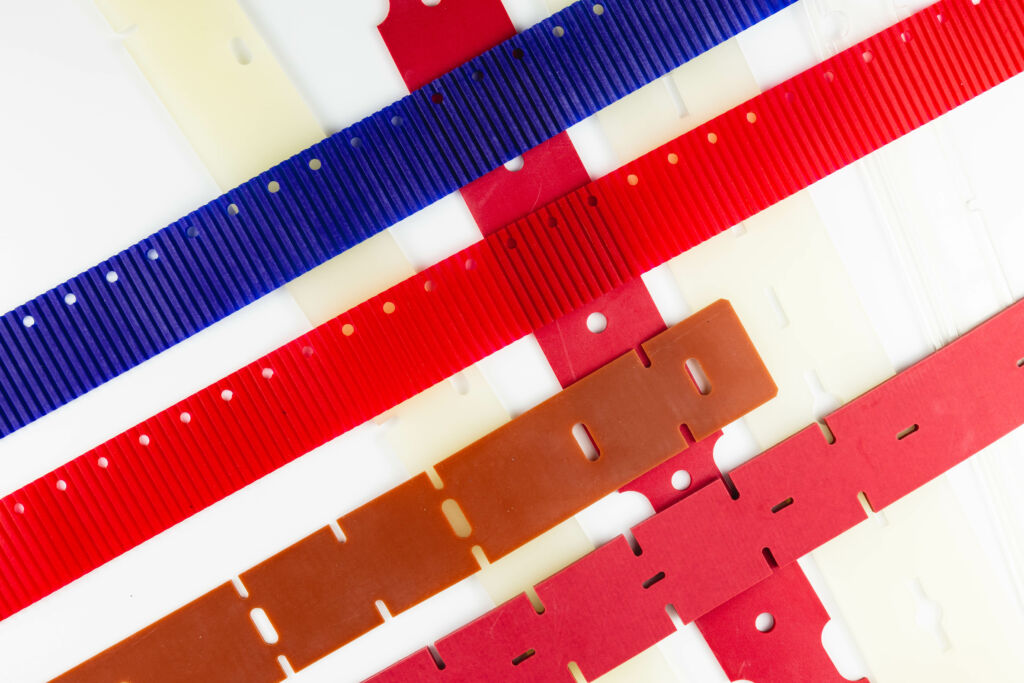

We specialize in the making of various flat shaped products according to order, according to drawing documentation or samples, which can be used in a wide range of areas.

For this purpose, we use a digital plotter knife that precisely cuts the selected material on a vacuum table. The dimensions of the work table are 2,810 x 1,500 mm, with a maximum material thickness of up to 50 mm.

In addition, the machine has a milling unit that allows us to create various grooves and other elements for our products. It is also possible to perform machine marking and labelling of parts or seals.

- Various sound-insulating (cutting of sound-proof boards) or heat-insulating elements

- Customized foam fillings - for example, for storing tools, electronics or fragile goods

- Flexible disks

- Customized shape cutting of floors = foam or rubber floors made of individual parts that are joined together by a shape joint (puzzle)

- PVC door strips

- Production of covering or protective strips for blasting or painting booths

Materials for the production of seals

In addition to the standard range of flange and pipe seals according to the applicable standards, it is also possible to produce various flat gaskets based on the provided drawings in various formats such as PDF, DWG, DXF, STEP and others. We also offer various types of sealing tapes, seals for historic cars and seals for screw joints. Some materials can be provided with an adhesive layer on request, on one or both sides.

- Asbestos-free sealing plates (GAMBIT, KLINGER, TEMAC)

- Rubber - SBR, NBR, CR (Neoprene), FKM (Viton), EPDM, Para rubbers - NR, Silicone, Butyl, Hypalon

- Foams and porous materials

- Plastics - PTFE (Teflon), PE, PVC

- Graphite

- Polyurethane

- Sealing paper

- Rubber cork

- Paperboard - cardboard

- Felt

- Electrical insulation materials

- Thermal insulation materials

- Soundproofing materials

- Leather

- Membrane canvases

Are you interested?

Do you need a customized seal for your specific project?

Trust us with your requirements and we'll prepare a specific solution for you,

that fits perfectly. Contact us today!

Why choose us?

Our company has been specializing in custom machining of plastics and rubber for more than 5 years. Our experience and constant focus on the quality enable us to deliver solutions that exactly match your needs. Read a few key reasons why you should work with us.

Every order is unique to us. We carefully communicate with every client in order to understand their specific needs and choose a solution that suits them exactly.

We use only high-quality materials, which makes our products last longer and offer optimal performance in various conditions.

By investing in the state-of-the-art technology and machinery, we are able to make products with high precision and in short lead times.

Our team consists of experts who are constantly learning and improving in their field. This enables us to guarantee the quality and reliability of all our products.

testimonials of our clients

Velmi oceňujeme Vaši odbornost, pečlivost a rychlost, kterou věnujete našim potřebám. Spolupráce s Vaší firmou je pro nás velmi přínosná, a to zejména díky profesionálnímu přístupu a rychlému řešení našich požadavků.

Na vaší firmě si vážíme především rychlé, jasné a výborné komunikace a slušného jednání. Déle spolehlivosti, včetně termínů dodání, což bohužel v dnešní době u každého dodavatele není.

Rychlost dodávek a 100% kvalita u všech dodávek.

Komunikace a pomoc při řešení složitých případů.

Pro výrobu našich produktů je klíčová nejen stálá kvalita a dobrá cena, ale také podpora při vývoji a inovacích. Invarex nám vždy nejen navrhne vhodný materiál, ale také dodá ověřovací sérii.

Naše spolupráce probíhá již několik let na velmi profesionální úrovni, oceňujeme komunikativnost a flexibilitu, rychlé řešení našich objednávek, technickou podporu a rychlost dodávek.